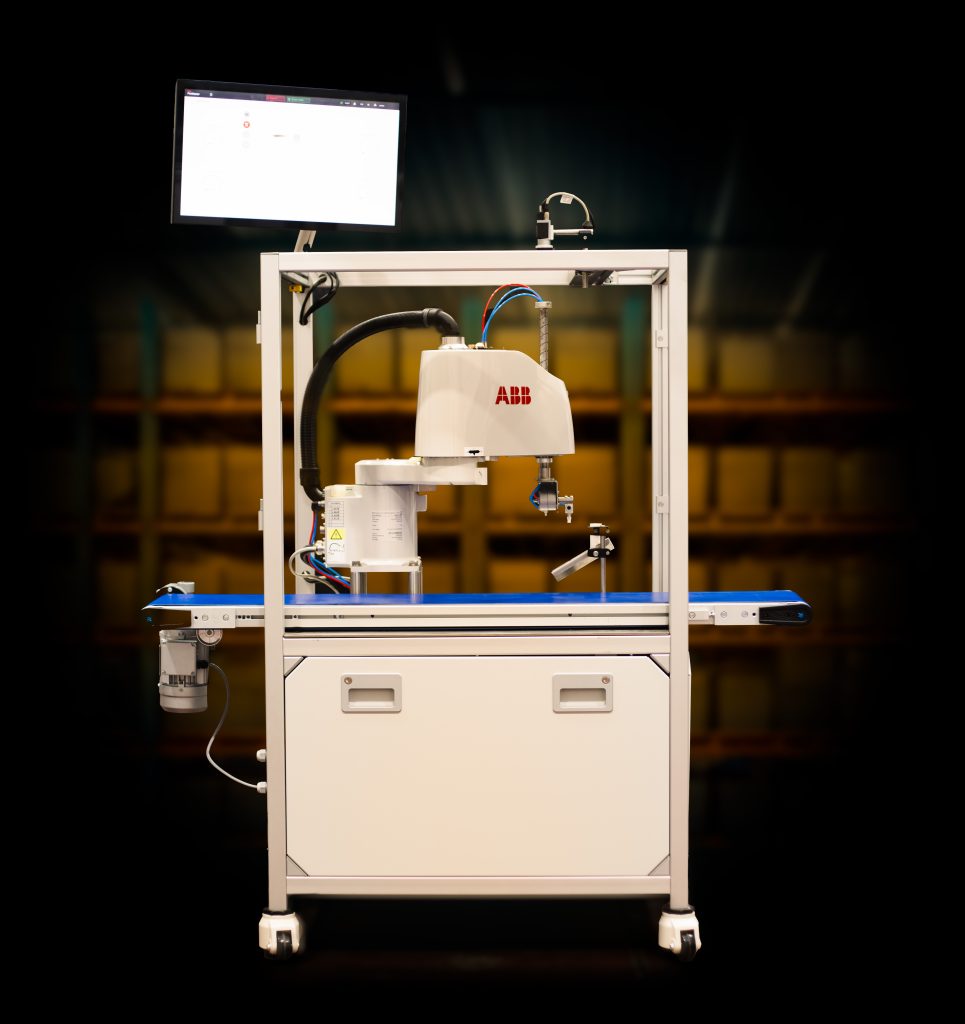

Automated system for detecting the orientation of pre-rolled cannabis cigarettes on a conveyor using an advanced camera system, and transferring them for further processing.

Project Application

Supply Scope

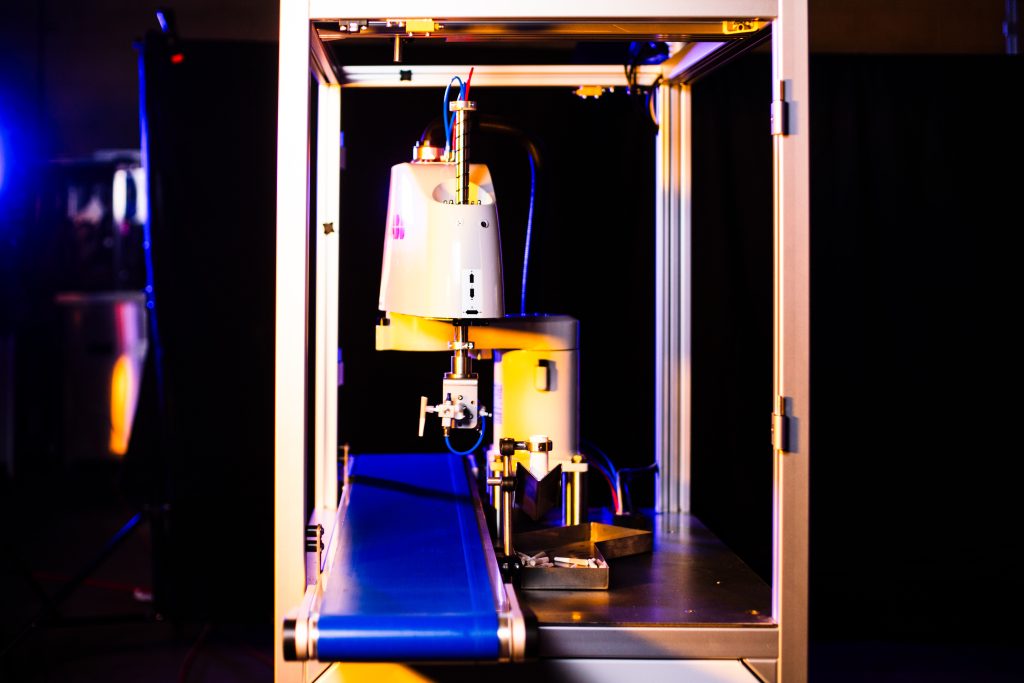

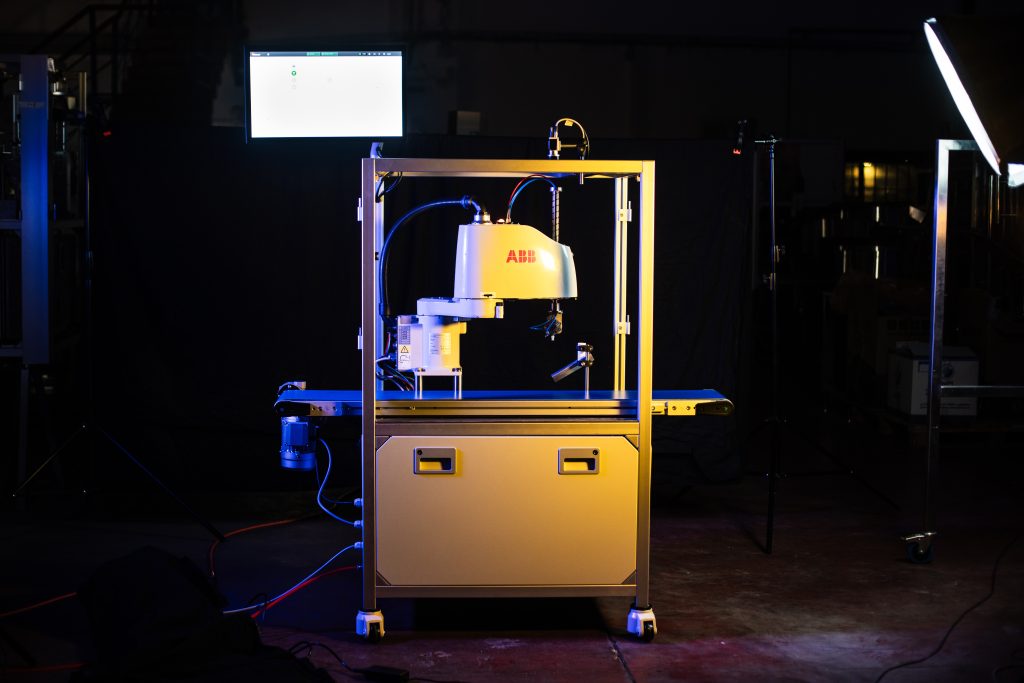

In collaboration with Hefestus, Shaniv Control developed a dedicated automation unit that handles pre-rolled cannabis cigarettes arriving on a conveyor in random positions and orientations.

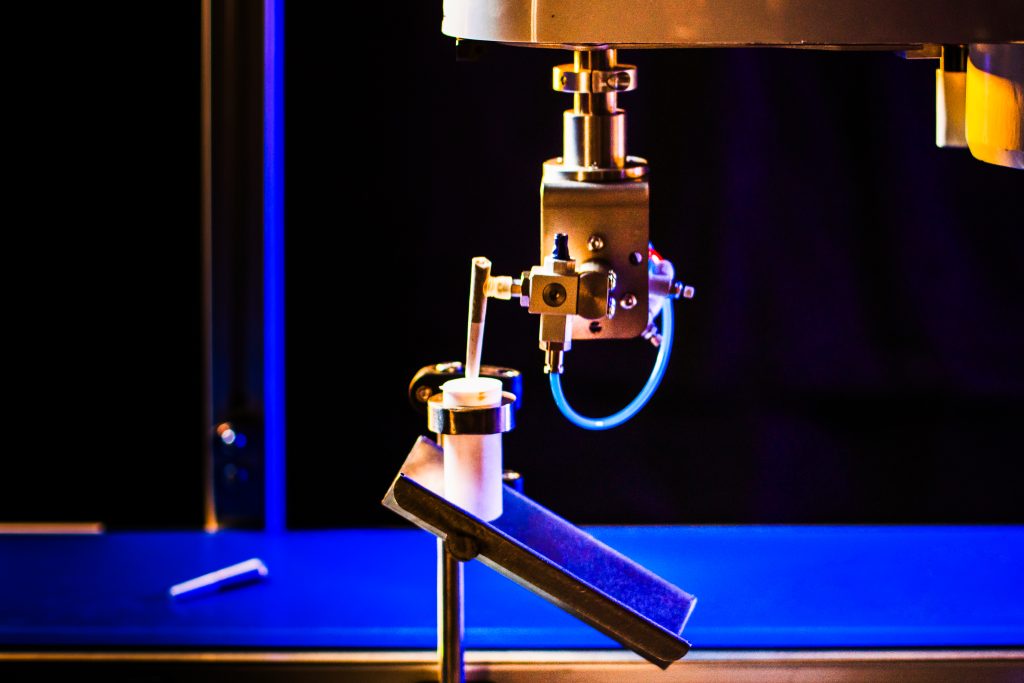

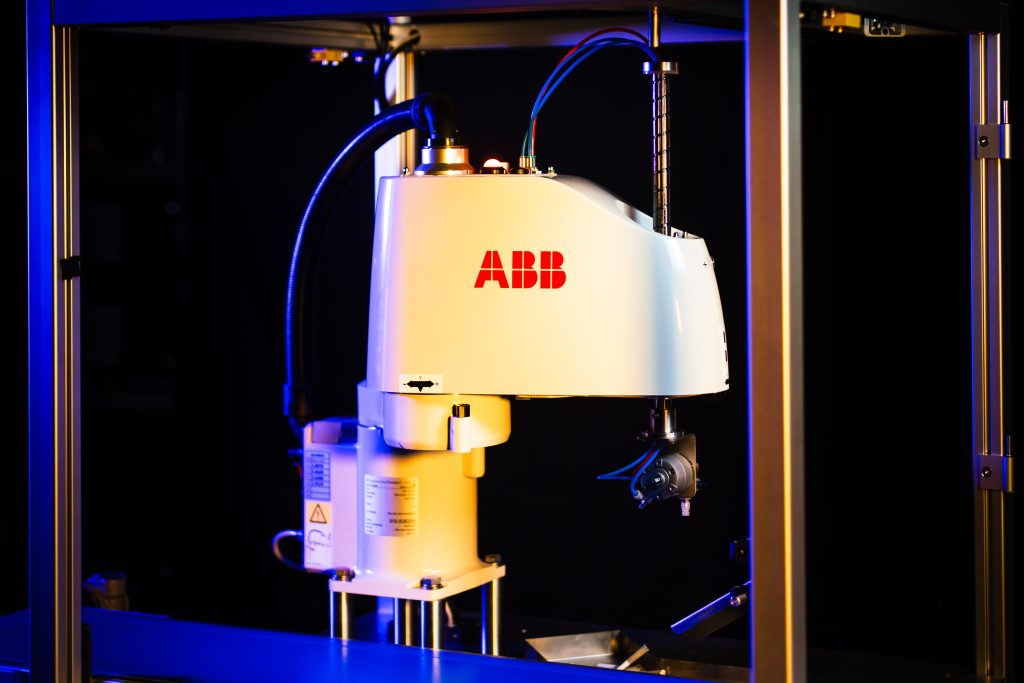

The system features a vision camera that detects the exact location and angle of each roll on the conveyor belt. The information from the camera is processed in real time to determine the orientation and positioning of every roll. An ABB SCARA robotic arm, integrated with custom tooling, picks each roll individually—regardless of how it’s positioned—and transfers it precisely to the next stage of production.

Shaniv was fully responsible for:

-

Integration of industrial vision camera for orientation and position detection

-

– Real-time processing of camera data for robotic picking

-

– Robotic system design and programming

-

– PLC and SCADA implementation for full process control

-

– HMI for live machine monitoring and diagnostics

-

– Conveyor control, safety logic, and synchronization